HUMAN FACTOR CHALLENGES IN LINE MAINTENANCE

HUMAN FACTORS IN AVIATION

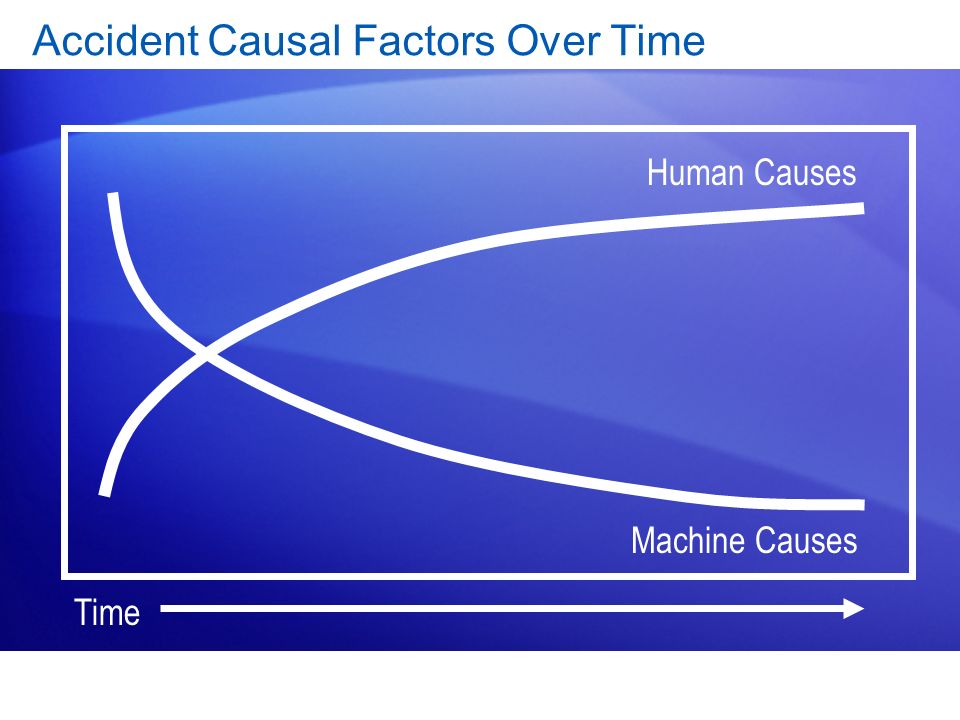

Human factors in aviation are any human-based element that affects and influences other factors in the aviation industry. As technology advances, machines become smarter and more reliable, making flying a safer mode of transport. However, we still see aircraft accidents happening even in this technologically advanced age (ICAO, 1984). This is because humans are not perfect and continuously make errors. Therefore, to minimize such human-influenced mistakes, the need to study human performance in the aviation industry arose. A few years back, I took a human factors examination paper in preparation to be certified as a licensed aircraft maintenance engineer. It is one of the papers required for anyone who intends to work in line maintenance, not just engineers. This goes to show just how important it is to understand human factors when working in the aviation line. Of all the 15 papers needed to become a certified aircraft engineer, human factors are the only paper that requires a 5-year renewal, whereas the other papers can be renewed after 10 years. This really left an impression in my mind because it emphasizes how human factors is always changing as it is human nature to never stay constant. Therefore, human factors is ever-changing, and the aviation industry must keep up with this change to lessen the number of accidents caused by human error.

Figure 1. A graph showing how human is becoming the main cause of aviation accidents as time goes by.

HUMAN FACTORS DURING LINE MAINTENANCE

The team-based activity I chose is line maintenance. From my personal experience, the common challenges faced affected by human factors is communication and pressure.

COMMUNICATION

Figure 2. A photo of two people on the line communicating with each other

In line maintenance, the work never stops. Therefore, employees are made to do shift work and each team would be split up into different shifts. The first thing about working in shifts on a long task is that the task would be handed over to multiple teams before completion. While handing over a task, there is a higher chance of miscommunication as the modes of communication are limited to written information with minimal verbal interaction. As written information is usually passed down from one person to the whole of the next shift, not everyone from the previous shift can provide their inputs. There is also room for misunderstanding as the end reader is unable to immediately clarify doubts and read the tone of the message. This may result in delayed or mistaken tasks, sabotaging the job at hand. To resolve this, the team across shifts can standardize paperwork by adding on or removing items from the hand-over checklist. This way, the paperwork can adapt and change to become more refined and understandable by team members across all shifts. This can help reduce misunderstandings and also improve the mode of communication between shifts.

Line maintenance also faces a lot of Aircraft On Ground (AOG) repairs which has a shorter completion target period as the aircraft is scheduled to fly as soon as possible. This may put pressure on the team to complete the work fast. When under time pressure, workers may cut corners and hide information from their customers or upper management so that they can release the aircraft on time. This is a challenge as a team working on an aircraft should always verify each other’s work and ensure that the aircraft is airworthy before sending it back to the customer. If time pressure causes the team to cut corners, there is a high risk of an accident occurring. To resolve this, it is up to the team lead to understand the team’s capabilities and set their expectations accordingly. This way, it can be ensured that team members would be able to put in their best work without getting too pressured when they are unable to reach a target.

References

Driskell, J. (1992). Crew Resource Management: An Introductory Handbook [Ebook]. FAA. Retrieved 11 September 2020, from https://books.google.com.sg/books/about/Crew_Resource_Management.html?id=2fk5AQAAMAAJ&redir_esc=y.

Federal Aviation Administration (2018). Aviation Maintenance Technician Handbook-general. Retrieved from https://www.faasafety.gov/files/gslac/courses/content/258/1097/AMT_Handbook_Addendum_Human_Factors.pdf

ICAO. (1984). Accident prevention manual [Ebook] (1st ed.). Retrieved 11 September 2020, from https://books.google.com.sg/books/about/Accident_Prevention_Manual.html?id=VTMY_zypRA0C&redir_esc=y.Federal Aviation Administration (2018). Aviation Maintenance Technician Handbook-general. Retrieved

Hello SH,

ReplyDeleteI enjoyed reading your blog, I also talked about communication from my blog. Communication is very important to aviation. I totally agree with you when it comes to communication. Verifying each other job is very important to aviation maintenance, we're all humans and we make mistake sometimes that's why communication is the key to this job. I used to work at Turbine engine overhaul shop as technician assembly. We have 3 different shifts. The way my company handle the 3 different shifts was, they were giving us 15-30 minutes to come early before our shift start so that we can get their turn over of whatever task they left off. For example first shift start at 7:00AM and they go home at 3:30PM, second shift start at 3:00pm so there is 30 minutes to get turn over to whatever they left off. Sometimes miscommunication happens, but we can avoid that by setting up a meeting between the shifts, having 15-30 minutes to give turn over task to the next shift will improve the lack of communication.

Hello SH,

ReplyDeleteGreat job on your blog for this week. The way you explained your personal experience on some of the most common challenges you face during line maintenance. The real life explanations like work never ending or miscommunication from one person to another are very realistic in a lot of job fields out there. The way you explained was really good to picture and grasp the knowledge that you were explaining, good job and keep up the good work.